|

|

Hyperion Z-Series |

HYPERION Z-Series Brushless OutRunners |

|

|

The new Z-Series Hyperion Outrunners are some of the best-built motors we have ever seen. From front to back, only the highest quality materials and components are used. The arrangement of twelve stator poles and fourteen magnet poles is primarily responsible for the high torque the Z Series generates on direct drive. But there is much more to the "Z" than that. The stators are hand-wound in an optimal pattern for copper packing, so we get less resistance for a given number of turns. The stator plates are produced via a CNC process that insures uniformity, and made of a new silicon steel with superior permeability at high induction. The stator plates are finished with a lifetime anti-oxidant coating, to eliminate losses which can occur due to magnetic shorting from corrosion. |

The magnets are especially made for the Z Series motors,

and are rounded

on both bell and stator sides. The result it that

contact area with the bell is complete, and this has two benefits:

First, heat transfer is maximized, so the magnets are much less subject

to damage from overheating. Second, the full contact with the bell on

one side, and matching curvature to the stator on the other, means that

the magnetic flux lines are complete and optimally shaped; this means

higher efficiency, lower incidence of motor stalling, and smoother

starts. The magnets themselves are produced in one of the foremost

factories in the world, and are the latest type, featuring both an

extremely high temperature rating and high magnetic strength. They are

retained by fingers in the bell-end, and attached with a special

high-temp glue made for the Japanese space program. We think it's just

about impossible to throw a magnet, or termperature de-mag these motors,

and we've tried very hard... Finally, the high-speed, shielded

stainless bearings in the Z Series are made by NMB Japan; expensive for

Hyperion to install, but well worth it for smoothness and longevity. As

you'll see in the specifications and prop data, the Z-Series have very

high power-to-weight ratios. The Z2209-32 at only 41.7g, for instance,

is a tremendous performer on 3S li-po and 10x3.8 APC SF prop in E3D

models weighing up to 350 grams. |

|

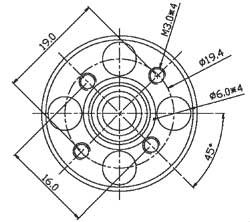

| Side View Z2209 Back View Z-Series Front View Z-Series (see dimensions above) | |

As you can see, the shaft arrangement makes it easy to front or backmount the motors, and use either a M5 x 3mm collet adapter or a prop-saver adapter. The shafts, retained by setscrew, are easily replaceable in the event of a crash, and are available for order. |

|

| Z2213

Motor with HP-Z22-BKMNT including HP-ADAP-30S Collet Adapter |

Z2205 Motor with Backmount plate and option HP-SAVER-30 |

|

|